MFL

Magnetic Flux Leakage

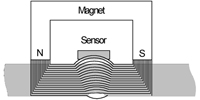

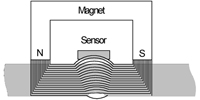

MFL – Magnetic Flux Leakage is an NDT technique which detects loss in volume of a magnetic material caused by corrosion or erosion. MFL locates defects by using a sensor to detect the magnetic field which is squeezed out of the metal wall under test by any decrease in the wall thickness. The sensor is usually one of two types:

This technique has found widespread use in the inspection of storage tank floors from the inside of the tank and in the in-service inspection of pipelines.

For more information on Magnetic Flux Leakage see:

'Magnetic Flux Leakage (MFL) Technology For Natural Gas Pipeline Inspection' at http://www.battelle.org/pipetechnology/MFL/MFL98Main.html#ProcessFlow

What the hec?! articles are not intended to be the definitive account on the topic or acronym in question. Readers’ comments and contributions are welcomed. Email: ndtnews@bindt.org

- a passive coil sensor – as the coil moves through the magnetic flux a current is induced and can be detected;

- a hall effect sensor – an electronic device which measures absolute magnetic field strength.

This technique has found widespread use in the inspection of storage tank floors from the inside of the tank and in the in-service inspection of pipelines.

For more information on Magnetic Flux Leakage see:

'Magnetic Flux Leakage (MFL) Technology For Natural Gas Pipeline Inspection' at http://www.battelle.org/pipetechnology/MFL/MFL98Main.html#ProcessFlow

What the hec?! articles are not intended to be the definitive account on the topic or acronym in question. Readers’ comments and contributions are welcomed. Email: ndtnews@bindt.org